The first thing to do is test the crystals for activity using an oscillator similar to the type the crystals will be used in. My trusty Conar 500 served the need. Testing will produce three piles of crystals. One pile for the duds and the other two will be for crystals that show activity. Most of the crystals will have a clean note but some will have raspy-sounding notes that are not pleasant to listen to. Each type will have its own pile.

Most of the crystals will still show activity sixty years after they were produced. The problem with practically all of the duds will be a broken connector between a pin and a contact. These crystals were discarded although some of the screws were salvaged.

My experience is raspy notes are caused by the holder and not the crystal. Unless the frequency of this crystal is ideal, these crystals may be discarded as well. With a selection of more than two hundred crystals discarding a few was not an issue.

The biggest pile will be then one with active crystals having good notes.

The next thing to do is decide upon some target frequency ranges. My preference is the CW portions of traditional HF bands. A selection of crystals with frequencies between 7000 and 7060 kilocycles would serve the purpose. Once my target was chosen I removed the crystals with frequencies between 6000 and 7050 kilocycles from the big pile.

The FT-243 crystal holders were assembled in two different ways. The style RCA produced used two screws between the pins to hold the cap on to the base. Internally the electrodes are plated on to the crystal blank. These crystals can not be easily re-ground, these can go back in the big pile.

At this point the selected crystals should all be similar to the one pictured above. This was the stock that was used to create my cache of 40 meter crystals. The total number of crystals I selected was about fifty, plenty considering the goal of twenty to twenty-five crystals with a few kilocycles between each.

Please note my facetious use of the word pile. The crystals should be handled in a reasonable manner. Rough handling may be the cause of broken leads.

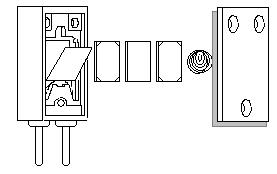

The image above is an exploded view of a FT-243 crystal. On the far left is the main body of the holder. Inside the holder are a pair of brass plates that are connected to the pins. The blank and its electrodes are found between these contacts. To the far right is the faceplate or cover. The shadow behind the cover represents a neoprene gasket and to the left off that is the tensioning spring. In the center are the two electrodes that sandwich the crystal blank.

When dis-assembling the holder try not to bend the leads to the contacts. A

small jeweler's screwdriver can be used to lever the outer contact if needed.

Pay close attention to the electrodes. One side will have lands in the corner

where the crystal blank makes contact. If an electrode is reversed when the

crystal is re-assembled the crystal may not oscillate.

Re-assembly is straightforward but cleanliness is essential. To clean the blank first hold it by opposite corners under running water. A soft toothbrush can be used the remove any stubborn grinding media. Next the blank is washed in alcohol. This is done by pouring the alcohol over the crystal not by submerging the crystal in a bath. Before re-assembly the blank needs to air dry. This is best done by resting one corner on a crystal pin with the opposite corner on the work surface. Drying can be sped up by placing the blank under an incandescent lamp.

Always handle the blank by the edges or corners. This reduces the chance of soiling the surfaces of the crystal. After grinding a blank wash your hands to remove any abrasives before re-assembling the crystal holder.

All that is needed to grind the crystals is some abrasive and a surface to grind upon. The grinding surface needs to be perfectly flat. I use a glass turntable salvaged from a discarded microwave. A piece of plate glass may also be used. Window pane glass is too fragile to use.

Initially I used scouring powder as the abrasive in the grinding slurry. It is effective but not abrasive enough when a crystal's frequency is to be moved several hundred kilocycles. When making large frequency changes a more abrasive slurry can be made using household copper polish. When selecting abrasives avoid those with additives such as scents, chlorine, anti-tarnish agents etc. Their presence is not necessary and may be detrimental.

Rubbing alcohol is used to clean the crystal prior to re-assembly. The brand I use is 70 percent isopropyl alcohol and costs thirty-nine cents a pint.

For a crystal to oscillate its surfaces must remain parallel. This is accomplished by using a semi-random grinding pattern. Most sources recommend using a figure eight pattern. I found it to be more comfortable using small circular motions. Which ever motion is used the crystal needs to "walk" around the grinding surface. I make small circular motions using my fingers while my hand moves about the circumference of a larger circle.

Hold the crystal by using downward pressure on opposite corners. Periodically reverse the direction of motion. The corners used should also be changed from time to time.

When the crystal is ground the grinding surface also gets ground and in time will become frosted. Moving about on the work surfaces helps prevent un-even wear of the glass.

There are two things that determine how quickly a crystal's frequency can be changed by grinding. The first is the amount of downward pressure applied during the grinding. This pressure should be constant and applied by the finger tips. The abrasiveness of the grinding slurry is the other factor.

My preference is to use a polish slurry for large frequency jumps. A scouring powder slurry is suitable for small frequency changes. I have found it takes about four minutes of grinding in the light slurry to move a single kilocycle. Four minutes of grinding using the polish is good for thirty to forty kilocycles. YMMV.

Regardless of the slurry type check the crystal's frequency often. I grind no more than two or three minutes before checking for oscillation and frequency. Grinding a crystal past the target frequency serves no purpose.

Amazingly enough my failure rate has been practically nil. There have been a few times when a re-assembled crystal failed to oscillate. The problem is almost alway caused by foreign material either on the crystal's surface or somewhere within the holder. Not using the alcohol as a bath stopped the problems with debris on the crystal blanks. Re-using the alcohol bath seems to add more impurities than than it removes. Still when a re-ground crystal fails to oscillate I re-wash the crystal.

At the same time the electrodes are washed in the same manner as the crystal blank is cleaned. I do swirl the case in bath and then rinse it just like the blank. Allow plenty of time for everything to dry as any moisture inside a re-assembled crystal will prevent oscillation.

My few total failures were caused by trying to move too far too fast. When more pressure is provided it becomes difficult to keep the pressure approximately equalized between between the thumb and finger. Grinding with noticeably unequal pressure will take the blank out of parallel.

How far is too far when moving a crystal's frequency? I have successfully moved a crystal's frequency over 900 kilocycles. That is a lot of grinding. Crystal grinding can be very tedious and tiring so keep the grinding sessions short. It took me a little over a month to produce my cache of 40 meter crystals.